Courses

We have created free-to-audit Mechanical Engineering MOOCs (Massive Open Online Courses) on the edX platform that we offer with direct links to open registrations.

2.008x Fundamentals of Manufacturing Processes

Study the processes used to manufacture products ranging from toys to smartphones, and learn fundamental principles and practical considerations that enable production at scale.

What You’ll Learn

-

Manufacturing processes in detail: machining, injection molding, casting, thermoforming, sheet metal forming, 3D printing, electronics assembly, and more.

-

Overarching principles: rate, quality, cost, flexibility, sustainability.

-

Design for manufacturing principles, how to plan a multi-step manufacturing process, and important life-cycle considerations of mass-produced products.

2.25.1x Advanced Fluid Mechanics 1: Fundamentals

Learn the fundamental principles underlying fluid dynamics; including the kinematics of deformation, hydrostatics & buoyancy, inviscid flow and the application of Bernoulli’s theorems, as well as applications of control volume analysis for more complex problems of engineering interest. *One of the 100 most popular university courses launched in 2021!*

What You’ll Learn

- Continuum mechanics

- Hydrostatics

- Buoyancy and rigid body accelerations

- Inviscid flow

- Application of Bernoulli’s theorems

- Applications of control volume analysis for more complex fluid flow problems of engineering interest

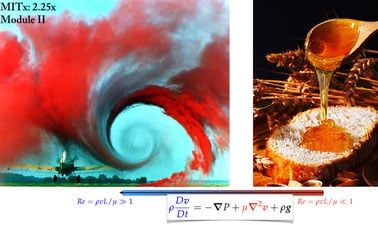

2.25.2x Advanced Fluid Mechanics 2: The Navier-Stokes Equations for Viscous Flows

Learn to apply the Navier-Stokes equations to viscous-dominated flows; including pipe flows, channel flows and free surface flows, use dynamical similarity and dimensional analysis, Stokes flows, similarity solutions and transient responses, lubrication analysis and surface tension.

What You’ll Learn

- The Navier-Stokes equation and appropriate boundary conditions

- The concept of Dynamical similarity

- Application of Dimensional analysis to complex problems

- Analysis of complex viscous flows such as Stokes flows or transient responses

- Lubrication Analysis for thin films and free surfaces

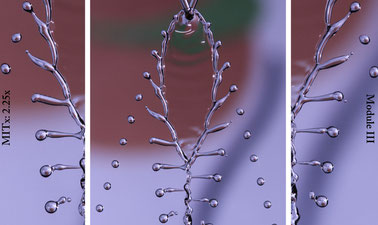

2.25.3x Advanced Fluid Mechanics 3: Potential Flows & Boundary Layers

Learn to analyze the structure of high Reynolds number inviscid flows using potential flow theory, the roles of vorticity generation in viscous boundary layers, circulation and lift, flow separation, and transition to turbulence.

What You’ll Learn

- Inviscid flows

- Potential flow solutions

- Vorticity

- Circulation

- Drag and lift

- Boundary layers

- Flow Separation and transition to turbulence

- Surface Tension Phenomena in engineering systems

2.005.1x Thermal-Fluids Engineering I

Coming Fall of 2022!

Other GREAT MIT Mechanical Engineering Courses

PoM

MicroMasters Program in Principles of Manufacturing

Develop the fundamental skills needed for global excellence in manufacturing and competitiveness with the Principles of Manufacturing MicroMasters® program credential, designed and delivered by MIT’s #1-world ranked Mechanical Engineering department. Build your career with the credential or use it as credits towards a Masters Degree by applying to MIT’s world-renowned Master of Engineering in Advanced Manufacturing and Design.

What You’ll Learn

- A new perspective for design and operational decision making at all levels of manufacturing, in the context of volume manufacturing, where rate, quality, cost and flexibility are the key metrics

- How to operate and control unit processes to ensure maximum quality

- Using basic and advanced statistical and feedback control methods

- How to design and operate systems of processes with optimal capacity, resilience and inventory

- How to design and operate optimal supply chain systems

- The financial underpinnings of a manufacturing enterprise, including new ventures

2.01x

Mechanics of Deformable Structures: Part 1

Study the foundational mechanical engineering subject “Strength of Materials”. Learn to predict deformation and failure in structures composed of elastic, elastic-plastic and viscoelastic elements.

What You’ll Learn

- Use Free Body Diagrams to formulate equilibrium equations in structural assemblages

- Identify geometric constraints to formulate compatibility equations in structural assemblages

- Understand the formulation of thermo-elastic, elastic-perfectly-plastic and linear viscoelastic models for the material response

- Analyze and predict the mechanical behavior of statically determinate and statically indeterminate assemblages with deormable bars in axial loading.